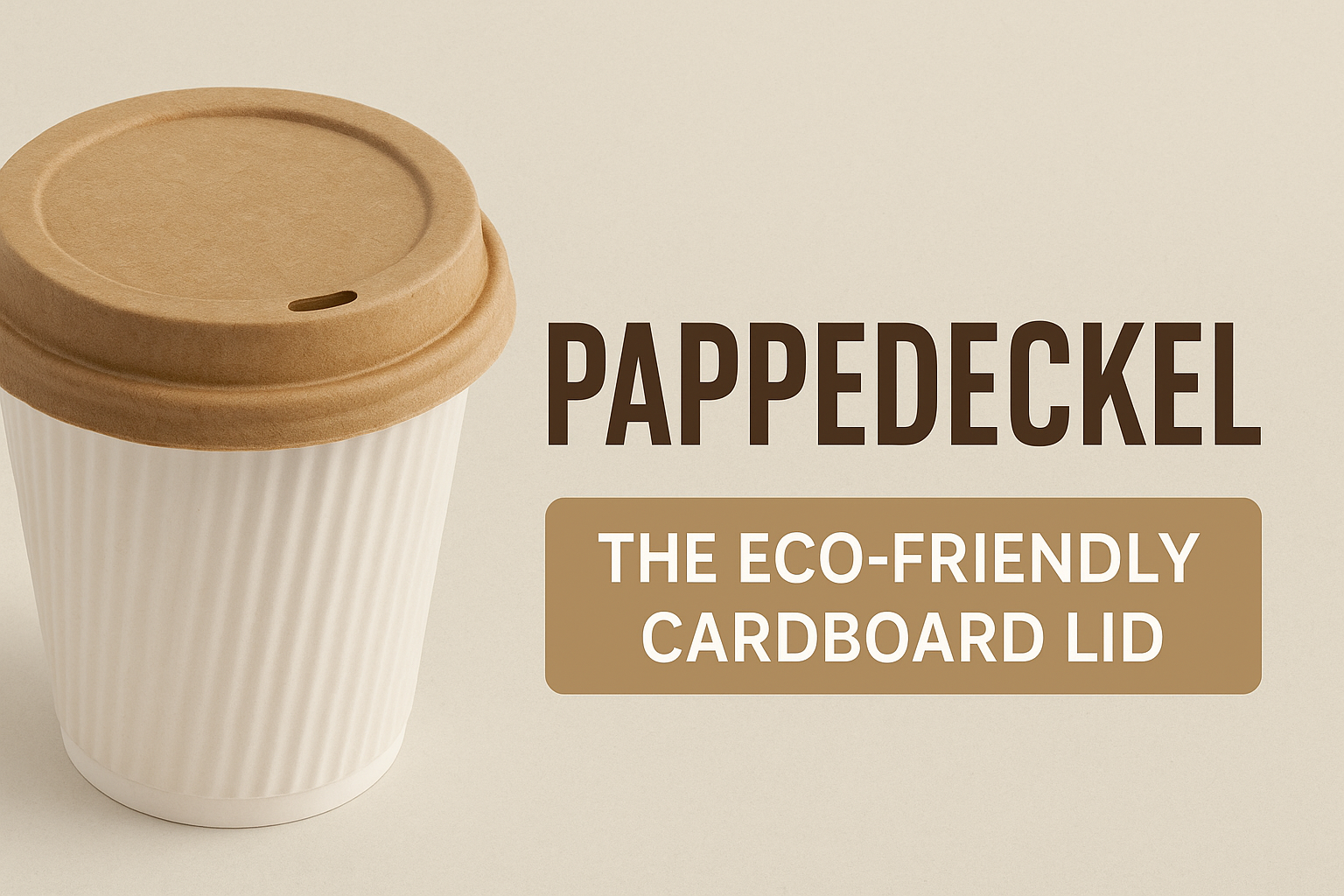

Pappedeckel: The Eco-Friendly Cardboard Lid Transforming Modern Packaging

Discover what a pappedeckel is, how it’s made, its uses, benefits, and why it’s becoming the sustainable alternative to plastic lids. A detailed, easy-to-understand guide on eco-friendly packaging solutions.

also read:https://theplaycentreorg.com/chas6d/

What Is a Pappedeckel?

The word pappedeckel comes from German, combining “Pappe” (meaning cardboard or paperboard) and “Deckel” (meaning lid or cover). In simple terms, a pappedeckel is a cardboard or paperboard lid used to cover cups, food containers, and packaging boxes.

Unlike plastic lids, which are made from synthetic materials, pappedeckel are made from recyclable and biodegradable paper fibers. They provide a lightweight yet durable solution to seal, protect, and insulate packaged items — especially food and beverages.

The Growing Importance of the Pappedeckel

Over the last decade, industries have been shifting toward sustainable packaging. Plastic pollution, government restrictions, and eco-conscious customers have forced brands to rethink their packaging choices.

The pappedeckel has emerged as a practical and eco-friendly solution, particularly in cafés, restaurants, catering, and retail packaging. It provides the same level of functionality as plastic but with a fraction of the environmental impact.

How Pappedeckel Works

A pappedeckel acts as a protective lid that covers or seals an opening. When used on a cup or container, it:

- Prevents spills and contamination by keeping the contents secure.

- Maintains temperature, helping keep beverages hot or cold.

- Adds structural support to thin-walled packaging, improving strength.

- Acts as a branding surface for printing logos, slogans, or QR codes.

In short, the pappedeckel isn’t just functional — it’s also a communication tool and a statement of sustainability.

Materials Used in Making Pappedeckel

Most pappedeckel are made from sturdy cardboard, kraft paper, or recycled paperboard. Depending on their purpose, they may be single-layered or multi-layered for extra rigidity.

| Material Type | Description | Key Benefit |

|---|---|---|

| Recycled cardboard | Made from reused paper fibers | Reduces waste & eco-friendly |

| Kraft paperboard | Unbleached natural fiber | Strong and sustainable |

| Coated paperboard | With a thin barrier layer | Resistant to moisture & oil |

The coating is often biodegradable (for example, using plant-based wax or water-based polymer). This ensures the lid doesn’t soften when exposed to hot drinks or moisture.

Manufacturing Process of Pappedeckel

The production process of a pappedeckel involves several eco-conscious steps:

1. Pulping & Sheet Formation

Raw or recycled paper fibers are pulped and formed into sheets of specific thickness. The sheets are then dried and pressed to achieve the right density.

2. Cutting & Shaping

Machines cut the sheets into precise shapes — circular, square, or custom die-cut lids.

3. Printing & Branding

If required, logos or patterns are printed using eco-friendly inks. This transforms a simple lid into a marketing tool.

4. Coating & Finishing

A thin coating is added to resist moisture and oil while keeping it food-safe and recyclable.

5. Quality Check & Packaging

Each lid is checked for fit, durability, and hygiene before being packaged for shipment.

This sustainable production cycle ensures that each pappedeckel meets modern packaging standards without harming the planet.

Advantages of Using Pappedeckel

The reason so many businesses are switching to pappedeckel lies in its many benefits:

1. Environmentally Friendly

Made from renewable resources, the pappedeckel is 100% recyclable and compostable, reducing plastic waste drastically.

2. Lightweight Yet Strong

It’s surprisingly sturdy for its weight, providing secure sealing and protection during transport.

3. Customizable

Brands can print on the lid for advertising or aesthetic appeal, making every cup or box a small marketing canvas.

4. Cost-Effective

Production is simple and affordable compared to molding or injecting plastic lids.

5. Safe for Food Contact

Food-grade coatings and adhesives make it ideal for hot beverages, soups, or desserts.

6. Consumer Appeal

Eco-conscious customers increasingly prefer packaging that aligns with their values. Using a pappedeckel reflects responsibility and modern thinking.

Limitations and Challenges

Even though the pappedeckel is highly sustainable, it does have a few drawbacks:

- Moisture sensitivity: Without proper coating, it may soften or deform when wet.

- Limited longevity: It’s intended for short-term use rather than long storage.

- Barrier strength: Doesn’t match plastic in terms of complete liquid resistance.

- Recycling contamination: Food or oil residue can sometimes complicate recycling.

Despite these limitations, innovation in paper technology is rapidly addressing these issues through improved coatings and fibre blends.

Common Applications of Pappedeckel

The pappedeckel is incredibly versatile and used across many industries:

1. Food & Beverage Packaging

The most common use — covering coffee cups, soup bowls, yogurt cups, and take-away boxes. It maintains temperature and prevents spills.

2. Retail & Cosmetic Packaging

Used as inner covers or protective inserts for boxes containing delicate items like candles, creams, or accessories.

3. Shipping & E-commerce

Acts as a lightweight protective lid or divider within boxes, reducing product damage during shipping.

4. Events & Catering

Used at eco-conscious events for disposable cups and trays, ensuring a plastic-free serving experience.

5. Arts & Crafts

Because it’s easy to cut, print, and paint, pappedeckel are also used in DIY art, scrapbooks, and creative upcycling projects.

Pappedeckel vs Plastic Lid: A Quick Comparison

| Feature | Pappedeckel (Cardboard) | Plastic Lid (PP/PET) |

|---|---|---|

| Material | Paper-based fiber | Petroleum-based plastic |

| Eco-friendliness | Biodegradable & recyclable | Non-biodegradable |

| Durability | Moderate | High |

| Cost | Low to moderate | Moderate |

| Recyclability | Excellent | Limited |

| Temperature resistance | Good | Very good |

| Custom printing | Easy | Complex |

| Environmental impact | Minimal | High |

The table clearly shows that while plastic has higher durability, pappedeckel wins in sustainability, branding, and recyclability—making it the smarter long-term choice.

Sustainability and Recycling of Pappedeckel

The environmental value of the pappedeckel lies not only in its materials but in its end-of-life cycle.

- Recyclable: Can be processed with paper waste streams.

- Compostable: In industrial composting facilities, it decomposes naturally.

- Low Carbon Footprint: Producing cardboard uses less energy than plastic manufacturing.

For best results, users should avoid soaking the lid or mixing it with contaminated waste. Clean, dry pappedeckel can be recycled multiple times, supporting a true circular economy.

Future of Pappedeckel in Sustainable Packaging

The future looks bright for cardboard lids. As technology advances, next-generation pappedeckel will include:

- Waterproof biodegradable coatings made from cornstarch or plant polymers.

- Smart printing with QR codes for traceability and digital marketing.

- Hybrid materials that combine paper fibers with natural plant resins for higher durability.

- Zero-waste supply chains, where both cups and lids are made from the same recyclable material.

This evolution will make the pappedeckel not just a lid, but a key part of the sustainable packaging revolution.

Tips for Businesses Switching to Pappedeckel

- Choose FSC-certified paper sources to ensure sustainability.

- Test the fit and thickness with your cups or containers before mass use.

- Use water-based inks for printing.

- Educate customers about proper disposal and recycling.

- Highlight your eco-choice on marketing materials — it builds trust and brand value.

FAQs About Pappedeckel

- What is a pappedeckel made of?

It’s made of recycled or virgin paperboard designed to be sturdy and eco-friendly. - Is a pappedeckel waterproof?

Some versions have biodegradable coatings that resist water or oil for short periods. - Can pappedeckel be used for hot drinks?

Yes, they are commonly used for coffee, tea, and soups. - Are pappedeckel lids recyclable?

Yes, if kept dry and clean, they can be recycled with paper waste. - Can I print on a pappedeckel?

Absolutely. Businesses often use them for branding and promotional messages. - Does a pappedeckel cost more than plastic?

Usually not. It’s competitively priced, especially when ordered in bulk. - Is it safe for food contact?

Yes, as long as it meets food-grade safety standards. - Can pappedeckel be customized in shape and size?

Yes, manufacturers can die-cut them in any design or thickness. - How long does a pappedeckel take to decompose?

Typically within 2–6 months under composting conditions. - Is it suitable for cold beverages?

Yes, but make sure the lid is thick enough to prevent warping due to condensation.

Conclusion

The pappedeckel is more than just a cardboard lid — it’s a symbol of the shift toward sustainable, eco-conscious packaging. Its recyclability, customizability, and affordability make it an ideal alternative to plastic lids across industries.

As more companies and consumers embrace green packaging, the pappedeckel will continue to evolve — becoming stronger, smarter, and even more sustainable. Choosing it means making a small but powerful contribution to a cleaner, greener planet.

news via inbox

Mail us for latest news and updates